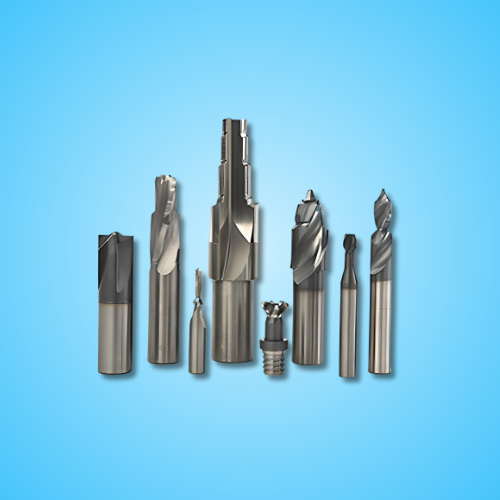

Profile Tools Built Around Your Component

Amech’s solid carbide and brazed tools are designed to match complex profiles, cavities, and special forms required in high-precision parts and moulded geometries.

Precision Where Standard Tools Fall Short

Solid Carbide/Brazed

Profile tools are rarely off-the-shelf — they’re engineered to match your part geometry and production demands. Amech delivers solid carbide and brazed profile tools that maintain dimensional integrity, edge quality, and tool life in demanding production environments. Whether it’s cavity milling, chamfering, or form drilling, our tools are made to match your drawing, not the other way around.

Contact our sales team to discover all of your pricing options

Explore Our Profile Tooling Capabilities

From single-step form tools to compound geometry cutters, we build to your component requirements.

- Combines boring and profiling in one operation

- Ensures dimensional repeatability across multiple features

- Ideal for reducing cycle time and tool changeover

- Designed for precision cavity shaping in mould and die applications

- Supports 2D and 3D profile generation

- Available in solid carbide or brazed design for roughing and finishing

- Multi-function tool combining drilling and facing

- Perfect for seat preparation, countersinking, or chamfered holes

- Reduces setup complexity and operation time

- For high-accuracy form profiles in mould, die, and cavity parts

- Maintains edge integrity even on hardened materials

- Built to match custom profiles or customer drawings

Where Our Profile Tools Are Used

These tools are ideal when standard cutters can’t match the part geometry — whether it’s in die-mould setups, multi-feature components, or high-volume machining of form-based parts.

Injection mould and die manufacturing

Automotive seat bracket and suspension parts

Aerospace structural components

General machining requiring specialized profiling