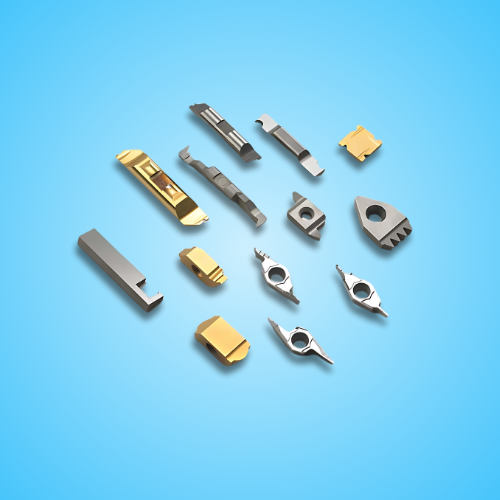

Custom Inserts for Precise Profiles and Tough Materials

Amech’s special inserts are engineered to handle complex cuts, grooving, and threading with consistent accuracy, even under high-load conditions.

Form-Perfect Cutting. Insert After Insert.

Special Inserts

Our special inserts are designed to match application-specific needs — whether you’re machining external grooves, internal threads, or customized profiles. We manufacture solid carbide and brazed inserts that offer sharpness, edge retention, and geometry accuracy, batch after batch.

Contact our sales team to discover all of your pricing options

Explore Our Special Insert Range

Built to suit your toolholder, machine, and material — with edge precision and coating compatibility for maximum life.

- Customized to match part-specific contours and cavity shapes

- Ideal for non-standard profiling and tight-tolerance finishing

- Used in die, mould, and production profiling tasks

- Designed for controlled face grooves with consistent depth and width

- Maintains tool stability and avoids chatter in wide-face operations

- Supports various chipbreaker and nose radius configurations

- Designed for external slots, undercuts, and precision shoulder grooves

- Supports heavy-feed, high-speed turning conditions

- Compatible with standard and special toolholders

- Available in partial or full profile threading styles

- Precision ground to match metric, UN, trapezoidal, or special thread forms

- Ensures clean entry, pitch consistency, and controlled flank finish

Where Our Special Inserts Perform Best

These inserts are used in specialized operations that demand consistent tool edge geometry and profile replication.

Turning centers and CNCs for mass-production

Aerospace and automotive threading and grooving

General engineering for external profiling

Die and mould cavity work